The intelligent sensing layer that powers predictive maintenance.

Avian’s thermal monitoring camera continuously captures thermal and RGB data, detects anomalies locally, and can even interface directly with your control systems to prevent damage.

Designed for Continuous Insight

The T100’s dual-sensor design, adaptive filtering, and real-time control capabilities work together to deliver actionable data for predictive maintenance and safety automation. Read our case studies for real stories from customer deployments

Dual Thermal + RGB Capture

Infrared and visible-light sensors capture synchronized temperature and visual data, aligning heat signatures with their exact physical context for fast verification.

Intelligent Scene Filtering

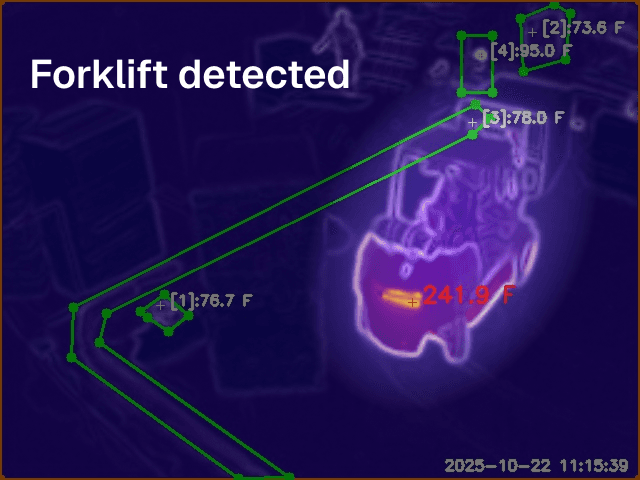

Cameras filter motion and irrelevant heat sources—like forklifts or personnel—so only stable, equipment-related temperature changes trigger evaluation and alerts.

Real-Time Control

Temperature thresholds and alarm rules sync automatically from the cloud. PLC, MQTT, or Modbus TCP integration enables automated machine stops.

Alarm

Full Feature Overview

Every T100 camera combines precision sensing, automated detection, and intelligent integration for continuous operation in industrial environments.

Monitoring & Coverage

Multi-Zone Configuration

Define up to 10 temperature zones per camera for precise monitoring of critical components and surfaces

Video Recording

Automatically capture RGB and thermal footage when alarms are triggered for post-event review and diagnostics

Live Streaming

Access real-time thermal and RGB streams from anywhere in the world through the Avian cloud dashboard

Detection & Alerts

Adaptive Thresholds

Temperature limits are dynamically adjusted based on learned baseline behavior, reducing false alarms while improving early detection

Multi-Level Alarms

Set independent thresholds for internal maintenance teams and for emergency escalation

Alert Scheduling

Apply time-based sensitivity settings — e.g., increased detection thresholds during unmanned shifts or night operation

Data & Reporting

Alarm History

Maintain a complete log of temperature events, alarm responses, and maintenance actions in a centralized dashboard

Automatic Reports

Generate compliance and predictive-maintenance reports automatically from stored trend data for each monitored region

Long-Term Analytics

Cloud-based storage supports time-series trend analysis, helping identify slow temperature drift and early component degradation

Integration & Control

PLC Connectivity

Send real-time temperature data and trigger automated shutdown or control actions via MQTT or Modbus TCP

Tamper Detection

Receive instant alerts if a camera is obstructed, misaligned, or loses connectivity

System Interoperability

Ethernet-based communication with Power over Ethernet (PoE) ensures seamless integration into existing industrial networks

Proven in Demanding Industrial Environments

The Avian T100 operates reliably in harsh, high-risk facilities — detecting abnormal heat patterns early, even in dust, vibration, and high ambient temperatures.

Wood Processing & Biomass

Sawmills, kilns, and pellet plants run at high temperatures and produce airborne dust — conditions where conventional fire sensors fail.

The T100 continuously monitors bearings, conveyors, and exhaust ducts for temperature drift, spotting ignition risks before combustion occurs.

Watch

Schilliger Holz — a 100-year-old European mill — uses Avian’s AI thermal monitoring to protect uptime and prevent failures across their planer and sawmill lines.

Recycling & Waste Management

Recycling lines and waste bunkers generate unpredictable heat sources from friction, contamination, and pile buildup.

With adaptive filtering, the T100 distinguishes between transient heat (vehicles, loaders) and sustained anomalies in waste piles or conveyors — triggering early alarms or automated PLC shutdowns.

Other Industrial Applications

While currently focused on the wood and recycling sectors, the T100’s environmental tolerance and integration capabilities make it ideal for:

Power distribution and electrical cabinets

Chemical and fertilizer plants

Food and feed processing

Material handling and bulk storage

Technical Specifications

Infrared Sensor

256 × 192 pixels, 8–14 µm spectral range

Temperature Range

–15 °C to +225 °C / +50 °C to +550 °C

RGB Sensor

12 MP, 66° or 102° FOV

Connectivity

Gigabit Ethernet (PoE IEEE 802.3af)

Integration

MQTT / Modbus TCP / PLC trigger

Ingress Protection

IP66

Operating Temp

–10 °C to +55 °C

Housing

Aluminum, 248 × 141 × 115 mm

Protect your facility today

Get tailored advice on fire prevention, risk reduction, and predictive maintenance insights for your facility